Franke Industries Hot Gas Path Products for the Aerospace Industry

Franke Industries is a reliable partner in fabricated and machined components for the gas turbine, aerospace and space industry.

With more than 60 years’ experience, Franke Industries resourcefully supports client projects from the first concept to the engine-ready component.

Franke Industries provides specialist services in hot gas path parts and subassemblies in stainless steel, high-grade alloys, titanium and heat-resistant materials in cooperation with market leaders.

One-stop-shop strategy for manufacturing aerospace solutions

Franke Industries’ one-stop-shop strategy offers customers procurement advantage.

The company maintains a network of specialised enterprises to offer clients the optimal manufacturing solution, from the very first sketch throughout serial production.

Products for the aerospace and IGT market

Franke Industries produces parts for the hot gas path such as burners, combustors, front segments, seals, heat shields and flame tubes. The company also supplies rings, ring-segments, bushings, brackets, and prismatic precision parts supplemented with special parts for the space industry.

The company is highly experienced in handling special alloys with a 0.3mm-35mm thickness.

The most frequently used materials from Franke Industries are nickel / cobalt-based alloys (inconel 600, 625, 718, 738, rene41, alloy 25, alloy 188, alloy 230, alloy 282, alloy-x, nimonic 75, nimonic 80a, and waspaloy), titanium, stainless steel, bronze, and aluminium.

In-house aerospace component manufacturing processes

Franke Industries offers the following in-house activities:

- Forming: deep drawing, inside / outside expanding, rolling, edge bending

- 2D laser cutting / 3D laser drilling (percussion, trepanning, hole diameter, starting from 0.5mm) and laser marking

- Machining: CNC milling (5-axis), CNC drilling (5-axis), CNC turning (5-axis), vibration grinding (deburring)

- EDM: Wire cutting and die sinking

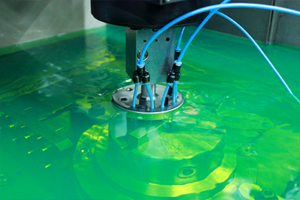

- Water jet machining: 3D cutting (5-axis), 3D drilling (5-axis), cold water and sand

- Welding: resistance welding (spot, seam) and tungsten inert gas (manual, semi-automatic and robot)

- Non-destructive testing: X-ray, penetrant inspection (red dye, fluorescent penetrant inspection, magnetic particle inspection), airflow testing

Quality management certifications

The management system at Franke Industries is based on the European Foundation for Quality Management (EFQM) model. It includes the following certificates: EN ISO 9001:2008, EN ISO 14001:2004, EN ISO 3834-2:2005, OHSAS 18001:2007 (EKAS), and DIN EN 9100:2009.

Franke Industries welding and non-destructive testing processes are Nadcap-certified.

About Franke Industries

Franke Industries is a member of the Artemis Group. It is based in Aarburg, Switzerland, and Ampfing, Germany. It currently employs around 140 employees with a net sale of CHF34 million in 2017.

Products and Services

Video

Related Projects

Press Release

Franke Industrie AG has acquired Ammatec GmbH in order to expand its aerospace market segment.

Read moreAfter exhibiting together with its partners from the Turbine Components Network over the last 10 years, Franke Industrie AG will start a new chapter this year.

Read moreFranke Industrie AG is pleased to start 2017 with a great achievement.

Read moreRegional Offices

Franke Strasse 2

4663 Aarburg

Switzerland

Wernher-von-Braun-Str 4

Ampfing

84539

Germany