YXLON International X-Ray Inspection and Computed Tomography Systems

YXLON International develops and supplies X-ray inspection and Computed Tomography (CT) systems and services for Non-Destructive Testing (NDT) systems and services worldwide, and thus helps its customers ensure product quality and improve their manufacturing processes.

X-RAY AND CT SOLUTIONS

YXLON International offers X-ray systems and CT solutions which fit into any manufacturing process in the aircraft, automotive, electronics, food or ship and vessel construction industries, to guarantee the highest quality and safety. This is verified by our status as an ISO 9001:2000 approved company.

YXLON International uses the newest trends in industrial non-destructive testing and has expanded its product range with CT solutions matching its customers’ requirements.

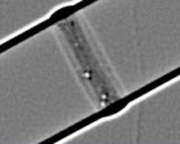

AEROSPACE WELD X-RAY INSPECTION

Weld inspection with X-rays is essential to fulfil the high safety standards in the aerospace industry.

Ducts, air channels and hydraulic lines in aircraft are exposed to the greatest mechanical and thermal stress, and therefore manufactured using special alloys. Elements like these are additionally supposed to exhibit a construction design that is as compact as possible. That, in turn, leads to complex geometric structures.

Welds are unavoidable with this type of construction. X-ray systems offer the possibility to inspect these welds with certainty.

X-RAY DIGITAL FLAT PANEL DETECTORS

Films are normally utilised as the imaging medium for weld inspection. However, the use of state-of-the-art digital flat detectors has now made it possible to increase weld inspection assurance with respect to defect recognition further, even when

X-rays must penetrate a double wall.

This procedure provides substantially reduced weld inspection times, and also renders the use of hitherto essential chemicals – and all their subsequent costs, such as chemical-waste disposal – unnecessary.

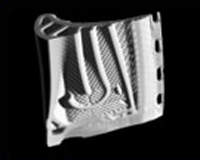

WELD INSPECTION X-RAY CABINET

YXLON also offers a specially developed X-ray cabinet system for weld inspection, which enables the necessary manipulation of welded ducts containing complex structures within the radiation step

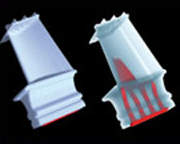

TURBINE BLADE X-RAY INSPECTION

Turbine blades are extremely complex manufactured parts with special needs for inspection, which can be met by X-ray inspection technology. The desire for a greater degree of turbine efficiency means that turbine blades are exposed to constantly increasing turbine inflow temperatures. The result is that an ever-greater perfection in cooling is required.

Pores in welded-on material, foreign substances in the cooling channels or incorrectly executed bores (for example, boring into the rear wall), can all be easily detected in turbine blades using X-ray inspection. For instance, the wide range of grey-scale dynamics displayed by digital detectors allows pores in welded-on material to be recognised with a single X-ray inspection of the turbine blade.

X-RAY COMPUTED TOMOGRAPHY

A measurement of turbine-blade wall thickness using ultrasonic technology is nearly impossible due to the turbulators or inner walls existing inside. Here is where the advantages of X-ray based computed tomography come to bear in turbine blade inspection.

Computed tomography enables a non-contact, reproducible measurement of all structures with high accuracy, even on an automated basis. In addition, computed tomography generates CAD data from the volumetric model, which makes a reverse engineering of the turbine blades possible.

X-RAY PRODUCT RANGE

Our product catalogue covers the whole X-ray field, including portable X-ray systems designed for on-the-field applications; standardised, modular X-ray and CT solutions; and complex, fully-automated, customised X-ray systems and CT solutions designed for specific applications. In addition, we offer installation, training, maintenance and remote-diagnostics on a 24hr basis.

UNIPOLAR X-RAY TUBES

From plastics to light alloys to steel, unipolar (or end-grounded) metal-ceramic X-ray tubes from YXLON International cover a wide inspection-range. Providing a high level of mechanical and electrical strength, YXLON’s unipolar X-ray tubes are both compact and lightweight.

BIPOLAR X-RAY TUBES

YXLON’s 320kV and 450kV bipolar metal-ceramic X-ray tubes are developed to inspect thick sections of high-density material, such as iron and steel castings. Providing a high level of mechanical and electrical strength, YXLON’s bipolar X-ray tubes are both compact and lightweight.

COMPLETE X-RAY SYSTEMS

Together with YXLON’s generators, power supplies and control units, YXLON’s unipolar and bipolar X-ray tubes form powerful X-ray systems, setting the standards for reliability, lifecycle and service.

X-RAY ACCESSORIES AND SOLUTIONS

YXLON provides portable, mobile and stationary X-rays instruments, and accessories such as X-ray tubes, detectors and displays. We also supply X-ray solutions for standard cabinets, and automated, pipe, wheel and tyre inspection, as well as customised products.

Products and Services

Video

White Papers

Press Release

YXLON International, a leading supplier of industrial X-ray inspection systems and industrial computed tomography (CT) solutions for the non-destructive testing of materials (NDT), is increasing its sales of standard rod anodes. Rod anodes from YXLON supplement the high-performance micr

Read moreYxlon International is a leading supplier of industrial X-ray inspection systems and computed tomography solutions for the non-destructive testing of materials on an industrial scale. With Y.HDR-Inspect, Yxlon presents its new standard solution for digital image generation in visual X-ray inspect

Read moreYxlon International is a leading supplier of industrial X-ray inspection systems and computed tomography solutions for the non-destructive testing of materials on an industrial scale. With Y.HDR-Inspect, Yxlon presents its new standard solution for digital image generation in visual X-ray inspect

Read moreRegional Offices

Essener Bogen 15

D-22419 Hamburg

Other

Germany