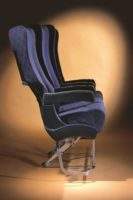

Seats of Australia Aircraft Interior Products

Seats of Australia (SOA) designs and manufactures aircraft interior products and SOA specialises in cabin interiors with an emphasis on aircraft seating and soft furnishing.

SOA’s main core business is to develop and distribute its Aerofoam product, as well support the aviation industry with cabin services including refurbishment of seats and manufacturing of covers and curtains. SOA has been distributing the Aerofoam product in Europe, Asia Pacific and Japan for the last 15 years.

The company can custom design your dress covers and cushions in partnership with you, to provide innovation that are not just comfortable and visually appealing, but that also suit the aircraft design and your budget requirements.

SOA’s wealth of experience and expertise within aviation soft-furnishing has attracted a global customer base, ranging from private jet owners to commercial airlines.

Aircraft interior manufacturing

We manufacture:

- Cushions / foams

- Dress covers (fabric, leather or laminated)

- Curtains

- Crew rest mattresses

- Crew rest mattress covers

- Thermo-formed (vacuum) plastic parts

- Non-structural cabin metal components

- Carpet cutting and sewing

SOA can design and manufacture cushions / dress covers to your exact requirements, and we can provide you with expert advice on a customised solution to provide the best appearance and maximum comfort to the end client.

Crew rest mattresses can be manufactured with our low resiliant foams to provide utmost comfort for the crew. With our highly trained machinists and technicians, we can manufacture the covers in various types of materials, for example, fabric, leather or vinyl, to suit operators’ requirements.

Aircraft interior maintenance

Seats of Australia offers a refurbishing service to repair or update aircraft seats to suit operators requirements. These refurbishments include:

- Cabin divider bulkhead

- Galley equipment, fittings and structure

- Interior trims, cushions, covers and carpets

- Seats, including cushions, covers and structure

- Foam upgrades

- Seat cover refurbishment

- Toilet bowl resurfacing (Teflon)

Our highly trained technicians have appropriate experience for stripping and rebuilding all types of aircraft passenger seats.

Cushioning research and development

SOA’s cushion designs are optimised and tailored to suit individual aircraft fleet operators’ requirements.

Ongoing research is conducted into new cushioning materials, that meet or exceed customers’ and statutory requirements. All our cushioning components are developed for optimum comfort, durability and ease of maintenance.

Pressure mapping and durability testing

SOA can provide a comprehensive pressure mapping report to identify pressure points and analyse the comfort levels of the cushions.

After the cushions are designed as per the approved specifications, they are put through a durability test. using the pounding test method to approved standards.

Flammability of interiors testing

SOA understands the significance of flammability requirements for aircraft interiors, so we can provide a comprehensive test plan for 12 sec vertical burn test and also the combination burn test; this test plan also includes all of the materials used to make up that product.

Seats of Australia is an approved organisation by the Civil Aviation Safety Authority of Australia, and holds the following approvals:

- CASA Production Certificate 555622-1

- CASA APMA 555622

- CASR Part 145 Approval (C6) – 1-QAW7Q

- CASA Certificate of Approval C 555622 CAR 30

- Boeing Approved Supplier

- CAAS Approval via Local partnership

- Approved Supplier to SJamco

Products and Services

Video

White Papers

Related Projects

Press Release

Regional Offices

52 Lillee Crescent

Tullamarine

3043

Victoria

Australia

41 Loyang Drive

Singapore

508952