AON3D Industrial 3D Printers for Thermoplastic Aircraft Parts

AON3D manufactures industrial 3D printers for high-performance thermoplastics, including polyether ether ketone (PEEK), polyetherketoneketone (PEKK), ULTEM™ 9085 and polycarbonate.

AON3D manufactures industrial 3D printers for high-performance thermoplastics, including polyether ether ketone (PEEK), polyetherketoneketone (PEKK), ULTEM™ 9085 and polycarbonate.

The company is dedicated to ensuring that designers and engineers have greater access to cutting-edge materials and affordable 3D printers, so they can drive innovation in the construction of metal-replacement components for the aerospace sector.

Open filament 3D printers for the aerospace industry

The use of 3D printing systems is becoming integral to the aerospace industry to decrease the weight of aircraft by enabling the usage of lighter components to replace metal parts, which will cut fuel costs and reduce emissions.

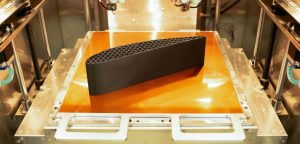

AON3D supplies printers built on an open filament platform, which provides thousands of options and allows users to print innovative materials. This is particularly useful for enabling advancements in the aerospace industry, where engineers require access to a wide range of rapid prototyping and end-use parts that fit their specific project needs.

High-performance thermoplastics and open filament 3D printing

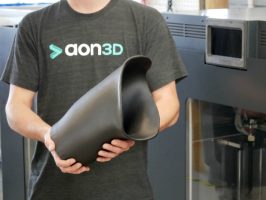

The AON-M2 is compatible with a range of high-performance thermoplastics from leading filament brands.

As the company’s flagship 3D printer, the AON-M2 is a direct response to demands for careful thermal control and hotter printing conditions. Most importantly, it offers an open filament platform that allows users to choose the right materials for their project and reduce costs by avoiding expensive proprietary materials and licence fees.

PEEK and PEKK for metal-replacement aircraft components

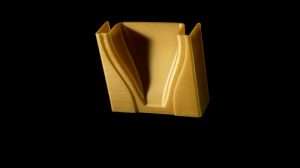

Widely regarded as one of the strongest thermoplastics, PEEK offers a highly sought-after combination of strong mechanical properties, along with thermal and chemical resistances. PEEK thermoplastics can be used to manufacture lightweight metal-replacement parts, as well as being capable of withstanding harsh working conditions and covering a wide range of operating temperatures.

With a similar mechanical strength and operating temperature range to PEEK, PEKK is a high-performance option that provides exceptional printability, even for large geometries. Advantages of PEKK include its use for compression-heavy applications, as well as its suitability for temperature and chemical resistant parts.

Polyetherimide (PEI) for reducing aircraft weight

Also known as polyetherimide (PEI), ULTEM is an affordable option that does not compromise its high-performance, maintaining an excellent strength-to-weight ratio and thermal resistance.

PEI is optimised for reducing the weight of aircraft, as well as being fully compliant with flame-smoke-toxicity (FST) regulations.

About AON3D

In 2015, a team of materials engineers from McGill University in Montreal, Canada, founded AON3D with the mission of advancing the world of 3D printing with high-performance thermoplastics. Previously dominated by machines that use costly, closed systems, AON3D has developed a line of industrial 3D printers that offer best-in-class performance at a fraction of the cost.

With more than 40 members, the AON3D team is equipped with expertise in materials science, engineering, additive design and applications support. From individualised setup training to materials selection to slice audits, AON3D is invested in ensuring that customers benefit from thousands of hours spent delivering high-quality 3D print runs.