Oldham Engineering Aerospace Design and Engineering Consultancy

Oldham Engineering is a turnkey project management specialist, providing in-house services of design, coded fabrication (BSEN ISO 3834-2), medium-heavy (30t – 10m) precision, computer numerical control (CNC) machining and robot welding, as well as complex assembly and testing for bespoke projects and batch production.

Our facilities include large fabrication areas, varied machining capacity and fitting department, which allows us to deliver a complete supply solution.

We have multiple qualifications and certifications, including ISO 9001:2015 and ISO 45001.

Aerospace design and engineering consultancy

Oldham Engineering’s team has acquired strong engineering knowledge, enabling us to guide our clients through the most complex projects, offering advice on best practice, current standards and product manufacturability.

We offer a complete engineered solution, which encompasses design, quality management, pre-manufacturing engineering review, process evaluation, project engineering and commercial NEC3 management.

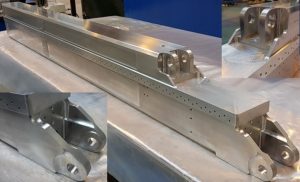

Aerospace industry fabrication and machining

Oldham Engineering services meet the highest industry standards across all sectors in stainless and carbon steel and exotic alloy fabrications. With 12,000ft² of the 80,000ft² site dedicated to stainless-steel fabrication, Oldham Engineering offers full segregation and ferroxyl testing.

With high-quality resources and an in-house resident welding co-ordinator (RWC) qualified to CSWIP 3.1 and PCN Level 2, Oldham Engineering provides ISO 3834-2-compliant services to support weld test qualification and NDE.

Our facilities include a number of large CNC machinery, offering optimum performance, reliability and accuracy. With high-end CNC machines, as well as horizontal and vertical borers, Oldham Engineering can deliver both custom and batch projects.

Ongoing investment in new machinery and technology is key to our business, ensuring we keep up-to-date with modern practices and offer our clients a high level of capability and competitiveness.

Fitting, testing and assembly for aerospace applications

Our skilled engineering fitters provide hydraulics, pneumatics and electronics solutions. Complex mechanical projects can be assembled to test interfaces of all components and working mechanisms and in-house test requirements for pressure, load, leak and factory acceptance test (FAT).

All of our fabrication, machining and fitting processes are rigorously inspected by qualified personnel, using our temperature-controlled inspection room, CMM inspection table and portable FARO arm. Our quality department ensures compliance throughout a project’s lifecycle and oversees that the required level of documentation and traceability is accurately recorded.

About Oldham Engineering

Family run Oldham Engineering remains a preferred supplier of high-integrity projects to key industrial sectors.

Our apprenticeship scheme allows us to develop skills in-house and contributes to the future of UK manufacturing.

Oldham Engineering is committed to investment towards structure and resource, as well as specially developed ‘business intelligence’ software that seamlessly integrates with real-time material requirements planning (MRP) and shop floor data capture system.

Products and Services

Video

White Papers

Related Projects

Press Release

Regional Offices

Castle Iron Works

Overens St

Oldham

OL4 1LA

United Kingdom