SIFCO ASC Selective Electroplating and Anodising Solutions for the Aerospace Industry

SIFCO Applied Surface Concepts (SIFCO ASC) provides selective electroplating and anodising solutions, including plating equipment, high-quality chemical systems, and expert training for the aerospace industry.

SIFCO Applied Surface Concepts (SIFCO ASC) provides selective electroplating and anodising solutions, including plating equipment, high-quality chemical systems, and expert training for the aerospace industry.

Selective plating for aerospace overhauls

SIFCO ASC’s portable method of electroplating sections of components without using immersion tanks is used in original equipment manufacturer (OEM) products and for restoring worn or damaged parts.

The company repairs damaged components on-site with its specially designed equipment and plating solutions, reducing major interruptions associated with disassembly and shipping.

There are many operational and maintenance challenges in the aerospace sector such as component wear, corrosion, fretting, and fatigue. SIFCO ASC offers surface treatments for corrosion protection, pre-braze, refurbishment and anodising.

Electroplated deposits for aircraft engineering

SIFCO Process® includes a full portfolio of electroplated deposits that meet the challenging specification requirements for landing gear, flap tracks, turbine casings and housings.

SIFCO Process® provides users with quality-controlled plating solutions, while minimising masking and disassembly for large parts.

The solution reduces production delays, downtime, and hydrogen embrittlement, while the process is environmentally friendly and offers alternatives to cadmium such as zinc-nickel and tin-zinc.

The SIFCO Process increases the service life of aerospace components through their quality plating abilities and have received several industry approvals.

The SIFCO Process® is used by the world’s leading aerospace companies.

On-site plating solutions for aerospace applications

SIFCO ASC has a team of experienced technicians that carry out on-site selective plating at any location.

Specialists offer recommendations on optimised solutions for individual clients and are skilled in plating a large variety of materials and parts.

Industry approvals include:

- AMS 2451

- MIL-STD 865 and 2197 (SH)

- MIL-I-45208

- FAA-Certified Repair Station

- ISO 9001:2008

- AS9100D-Registered Quality Management System

About SIFCO ASC

SIFCO ASC has more than 50 years’ experience in selective plating, while its SIFCO Process® is regarded as one of the best in the industry. Consultants and skilled technicians’ comprehensive research allows the company to offer in-depth engineering support and state-of-the-art plating equipment.

The company’s SIFCO Process® is used globally in OEM applications, as well as to repair and maintain important components for leading businesses involved in power generation, oil and gas, aerospace, precision engineering, and electronics.

SIFCO ASC is based in Independence, Ohio, US, and has offices worldwide, including the UK, France, and Sweden.

Please use the enquiry form for more information.

Products and Services

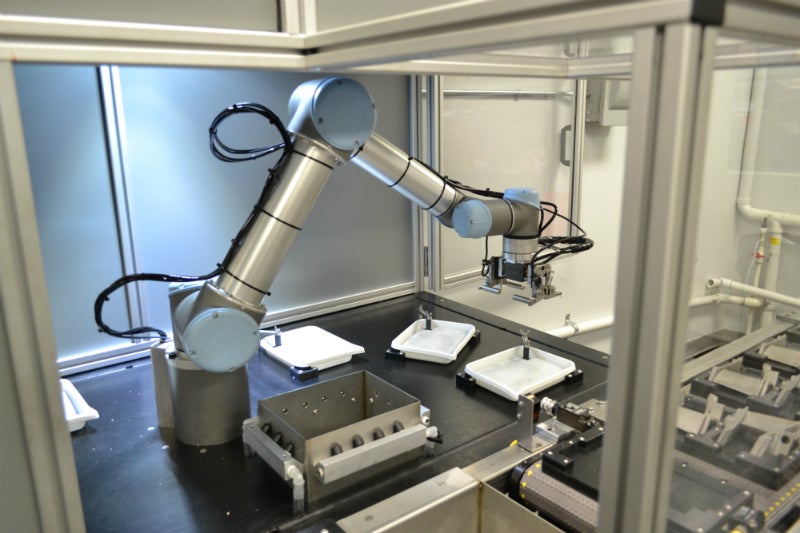

Automated Plating Systems

More and more companies are relying on the consistency and traceability that automated processes provide, so why would selective electroplating be any different?

SIFCO ASC Portable Travel Kit

SIFCO ASC portable travel kit allows for on-site touchup applications.

SIFCO Process® Training Programmes

SIFCO ASC has created a series of training programmes designed to meet specific customer needs.

Classic Power Packs

Classic power packs are well-suited to critical plating applications.

Anodes

SIFCO plating tools consist of an insoluble anode, normally graphite, and an insulated handle.

White Papers

Automated Selective Plating

Safran Landing Systems (formerly Messier-Bugatti-Dowty) is a world-leading manufacturer of landing gear systems.

Eliminating Ergonomic and Environmental Risks from Plating Operation

Based in Muskegon, MI, US, Johnson Technology, a GE Aviation subsidiary, is the leading manufacturer of aircraft engines and engine parts such as blades, vanes, turbines and hangers for the aerospace and power generation industries.

Brush Plating of Tin-Zinc Alloy as an Alternative of Cadmium

Sacrificial coatings are applied to surfaces both by bath and by selective brush plating to protect the underlying substrate from corrosion.

Making the Case for Selective Plating in Aerospace: A Technical Paper

It’s critical to enhance component performance and longevity, and protect or repair equipment.

Related Projects

Press Release

SIFCO ASC, the global leader of selective electroplating, has brought to market a new plating method named Encapsulated Plating, combining the technology of both selective plating and tank plating.

Read moreOn 1-31 March every year, we celebrate Women’s History Month to recognise the achievements of women all over the world.

Read moreQuaker Houghton has closed the acquisition of the operating divisions of Norman Hay plc, a private UK company that provides speciality chemicals, operating equipment and services to industrial end markets, for a purchase price of £80m ($98m).

Read moreIn aerospace manufacturing, the performance and reliability of components is paramount to delivering safe journeys, even in the face of extreme friction and temperature. But the challenges don’t end there.

Read moreSelective plating technology and solutions supplier SIFCO Applied Surface Concepts (ASC) is inviting customers to learn about selective plating and the benefits of automating the process at its free webinar.

Read moreSIFCO ASC has developed a power pack called TechnoPlate® to improve quality, flexibility and safety in the selective plating process.

Read moreThe US Secretary of Commerce Wilbur Ross has recently demonstrated SIFCO ASC's systems with the President’s “E” Award for Exports at a ceremony in Washington, DC, US.

Read moreSIFCO ASC will be attending the SUR/FIN 2019 conference in June and will be delivering a series of presentations as their expert team look at some of the leading trends and challenges of today’s surface finishing industry.

Read moreOn 24 April, SIFCO Applied Surface Concepts (ASC) is offering a free webinar to offer expert advice about the processes of selective plating and selective anodising.

Read moreRegional Offices

5708 E Schaaf Road

Independence

44131

Ohio

United States of America