Morgan Advanced Materials has further enhanced its range of market-leading products for the wind energy sector with the addition of a new brush gear for users of Vestas V52 to V80 series wind turbines.

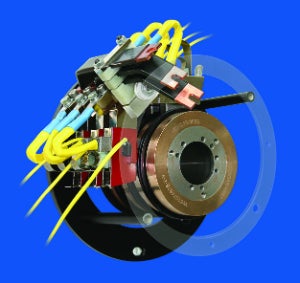

Designed to replace the calliper holders fitted as standard on these turbines, the new products draw on Morgan’s extensive materials expertise and application engineering knowledge to deliver a range of performance benefits.

These include extended service life, as well as considerably longer intervals between brush replacements thanks to a carbon brush wear length double that of the OEM part. The easy fit carbon brush holder system also means less time spent on replacement, reducing maintenance costs.

The products also boast constant force springs, which create stable and consistent spring pressure over the full operational length of the brush. This significantly reduces the potential for selective action therefore improving overall carbon brush life.

Brush wear alarm indicators are available as an additional option. The holders can also be nickel-plated to deliver optimum protection in offshore and coastal applications.

Gary Brown of Morgan Advanced Materials explained: "The diversity of the global environment has a great effect on the carbon brush performance of doubly-fed induction generators on wind turbines.

"Our lightweight, compact, high-performance solutions are designed to maximise current collector performance and so improve overall generator output."

Morgan Advanced Materials offers an extensive range of carbon brush and holder systems for wind turbine generators, including earthing, bearing and lightning protection as well a full pitch control units.