When human life depends on the equipment functioning properly, the highest precision and accuracy is a must. Something we once again got to demonstrate in a challenging assignment for Mirola.

Mirola develops advanced solutions for the distribution of oxygen in mobile oxygen equipment for humans. With their self-patented Mair Technology, they have taken mobile distribution of oxygen for advanced field care to a whole new level. The solutions are used by, among others, rescue services, military, and divers, and are much appreciated for their high efficiency and user-friendliness.

In order not to endanger human life and health, it is, of course, of the utmost importance that every detail of Mirola’s equipment is produced with the highest precision and accuracy. At LK Precision, we were commissioned to deliver the nozzle that ensures that the oxygen comes in the right flow. A challenging assignment that required careful tolerances in the manufacture of the hole, which measured 0.1 mm in diameter.

Mirola designer Fredrik Broberg said: “The nozzle is an absolutely vital part of the equipment. The slightest deviation entails great risks for the users. LK Precision delivers the high precision we demand and has serious delivery controls, which is why we chose them as a supplier. The end result was very good and we will continue to turn to them for continued collaborations.”

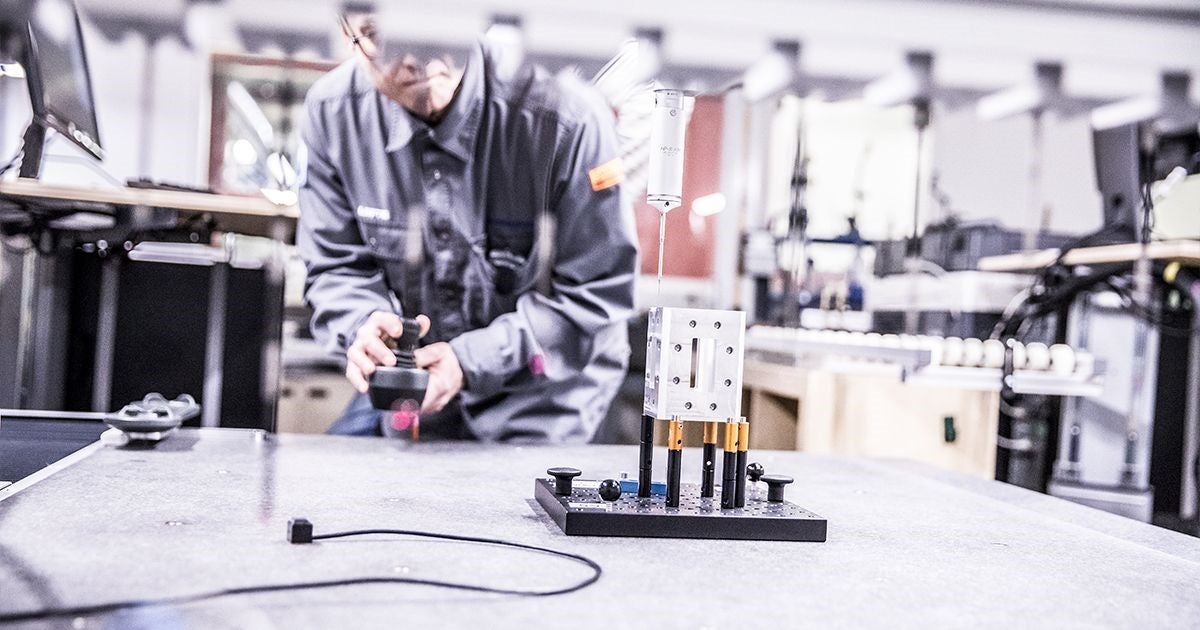

LK Precision’s assignment consisted of setting requirements for drawing, as well as manufacturing and verification of measurements and flow tests.

LK Precision Quality Manager Fredrik Mossberg said: “As always, it is important to get a quick start in the development of new products as the customer wants to enter the market quickly. This meant that we carried out the project all the way from setting requirements to manufacturing the first pre-series in about six weeks. Now we have received an order for series production of the nozzles and we look forward to continuing the collaboration with this exciting and important company.”